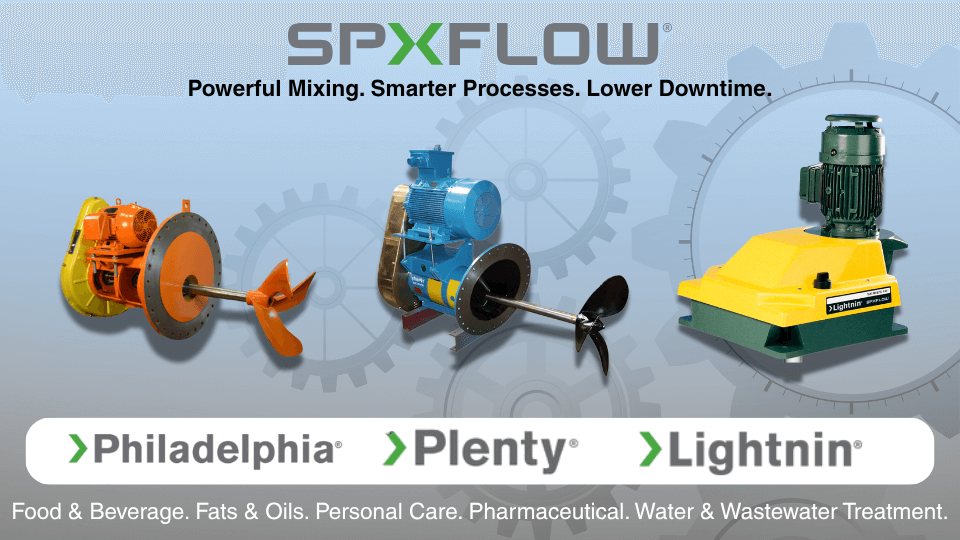

Centennial Equipment offers a variety of industrial and commercial mixing and blending equipment to meet the needs of a multitude of industry applications. We offer SPX Flow brands of Lightnin, Plenty & Philadelphia, as well as Quadro Liquid. This article discusses how we can meet the unique requirements of chemical, food & beverage, fats & oils, oil & gas, personal care, pharmaceutical, water & waste.

Chemical Processing Mixers

The chemical processing industry has very diverse requirements in their production of mass consumer products and vital raw materials. Utilizing the range from the SPX FLOW brand portfolio, we can research, develop and test customized chemical processing equipment optimized to the needs of our customers.

- blending

- suspending solids

- heat transfer

- solids wet-out

- polymerization

- dissolving

- shearing

- mass transfer

- complex chemical reactions

- hydrogenation

Download the Lightnin Mud Mixer Guide (PDF)

Download the Philadelphia Mining Gearbox & Mixer Reliability Case Study (PDF)

Food & Beverage Production Mixers

Food & Beverage production is growing in complexity, as consumers demand fewer, cleaner, and greener ingredients, as well as purity and taste. The ability to blend medically necessary or age-related ingredients with other ingredients that are there for taste, mouthfeel, and safety, for example, could be the key to product sales.

SPX FLOW brands bring you more than 50 years of experience in configuring production lines to handle both the complexities and the dietary requirements needed to make satisfying liquid meals.

Where traditional processes systems might require, for example, adding a surplus of vitamins and other nutrients to compensate for those that are chemically destroyed in production, our patented Instant Infusion process gently steams mixtures at high temperatures (135-145 degrees in 0.1 to 0.5 seconds).

This minimizes the impact on product quality, chemical changes in color, flavor and fat stability that could impact the marketability of the final product.

Our experts will work closely with yours to tailor unique solutions that incorporate world-class preparation, mixing and drying capabilities into a custom configuration that will give you a true market advantage. We stand committed to helping you address nutritional specifications, safety requirements and consumer trends with innovative, appealing beverages, at the lowest cost.

Fats and Oils Commercial Mixers

SPX experienced experts can work with you to create the most appealing fats and oils products. They know how to balance taste, optimize protein content and shelf life, ensure product stability, ensure spreadability or do whatever else it takes to ensure you high-quality products.

SPX FLOW integrates almost 120 years of exemplary fats and oils production experience into turnkey process solutions and world-class production equipment.

Our solutions will help you maximize product quality, production yield and food safety while minimizing raw material waste, operating costs, energy consumption and footprint. When it comes to processing fats and oils, we’ve seen and done it all.

Oil and Gas

SPX FLOW oil and gas side and vertical mixers are designed to meet the needs of upstream and downstream applications.

SPX FLOW is continually developing and advancing its technology to support the oil and gas industry growth by producing equipment to satisfy customer requirements in deeper water and higher-pressure environments.

Upstream

SPX FLOW mixing solutions for oil and gas assist in both upstream and downstream operations. Upstream drilling operations require the industrial drill bit to remain clean and with an even temperature. The condition of the drill bit hinges on drilling fluid, often a stabilized water-in-oil mixture, that requires the heavy agitation of industrial mixing technology to produce.

In the production of sample able crude oil, industrial mixing systems are used to spread the water content of the oil evenly for accurate measuring. This process takes place upstream as to sample the crude oil, however, downstream the oil and water mixture will need to be separated. Therefore, an upstream crude oil sampling mixer must be balanced enough to evenly mix the crude oil and water while not mixing the solution to the point of inseparableness.

Downstream

A downstream mixing application is required to prevent crude oil from solidifying in stagnant tanks. Once solidified the crude oil would be increasingly difficult to pump out, leading to significant time, production, and opportunity cost. A mixing application is utilized to prevent the stagnation of crude oil through perpetual motion of a mixing solution.

In refinement, large concentrations of carbon dioxide and sulfur dioxide are removed via industrial static mixers. Later in the process, additives are mixed into most petrochemical products before they are ready for market using an industrial mixing application.

Download the Lightnin Flue Gas Desulfurization Mixers Brochure (PDF)

Download the Philadelphia BSER Side-Entry Mixers Guide (PDF)

See how Philadelphia Advanced Pitch Propeller Mixers Reduce Energy Use (PDF)

Personal Care

The manufacturing of beauty, haircare, skincare, body care, oralcare and personal care products all vary from one product type to another. SPX FLOW application engineers have a depth of industry knowled

ge to construct hygienic, safe and quality personal care mixing solutions.

SPX FLOW personal and home care manufacturing equipment offers you the essential process characteristics needed to produce products repeatedly and to expected standards of quality to meet customer expectations. Engineered to meet your needs, SPX FLOW can offer:

- Crevice free design to allow clean-in-place (CIP) services

- Highly polished surfaces and electropolishing where needed

- Self-draining surfaces

- Hygienic mechanical seal designs

- Material Certification and Quality Assurance Documentation

- Accurate fixed or variable speed drives with shaft speed monitoring

Download the Lightnin Personal & Home Care Mixers Guide (PDF)

Pharmaceutical

Mixers capable of fully blending pharmaceuticals is the highest requirement for the pharmaceutical processing industry. To create consistent quality standards, each product must be well blended, and account for variances in the environments of the pharmaceutical production lines. This requirement, combined with the sanitary needs restricts the type of mixers to air driven and electric. Typical Pharmaceutical Mixing Applications include:

- vaccine production

- antibiotics

- mammalian cell cultures

- blood factors

- injectables

- buffer solutions

Download the Lightnin Pharmaceutical & Biotech Sanitary Mixers Guide (PDF)

Water and Wastewater Treatment

Water treatment mixing is centered on the coagulation of chemicals within tested water to cause nonsettling particles to form floc or a mass of solids. This process is carried by variable surface aerators design, therefore the key toeffective and efficient industrial water treatment is an optimized flash mixer. SPX FLOW brands Lightnin and Plenty utilize two emerging technologies to render accurate impeller performance and to optimize functional mixers design.

High Shear Mixing Applications – Powder Dispersion

Some personal care, pharmaceutical, food and chemical applications require powder dispersion. Quadro® inline mixers, industrial dispersers and emulsifiers/homogenizer mixers apply the required degree of shear to all the process material in a quick, single pass. These are high and low shear industrial mixers, expertly designed and engineered for performance.

The advantages of Quadro single-pass processing technology include:

- reduced batch processing times

- maximized use of raw ingredients for less waste

- highest process repeatability for product quality from the lab scale through to production

Parts, Maintenance & Modernization

To protect your investment, we recommend using OEM Lightnin and Philadelphia parts and taking advantage of modernization services to extend mixer life and reduce downtime.

Download the Lightnin OEM Parts & Service Guide (PDF)

Download the Philadelphia Mixing Operations Health Report Overview (PDF)

Whatever your application, Centennial can help you find the right mixing solution.