Product Description

CC - Close Coupled Motor Mounted Clean Water Pump

SUMMIT CC pumps are horizontal, end suction, centrifugal pumps certified to DOE requirements. They are designed to be an economical and dependable solution for general service such as clean water, solvents, light oils, non-corrosive chemicals, coolants and brines.

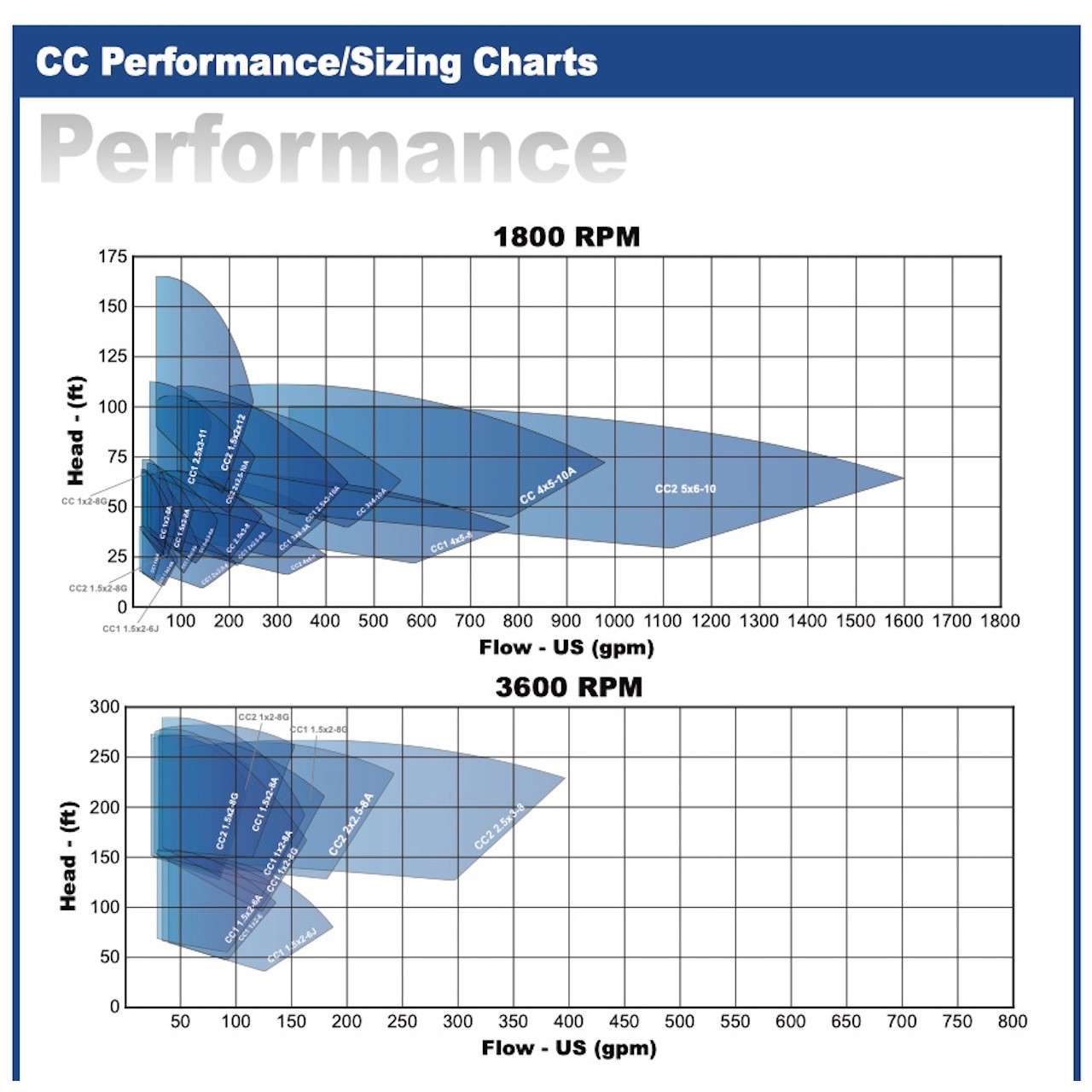

- Capacities to 2300 GPM

- Heads to 440 feet

- Flanges are 125lb ANSI B16.1 rating

- NPT connections are standard on 6” and most 8” sizes.

- A renewable bronze shaft sleeve is standard on cast iron pumps and a 316ss shaft sleeve is standard on alloy pumps.

- The close coupled pump is directly mounted to a NEMA “C” face motor, and designed to use minimal space. Motors with TEFC frames use a standard mechanical seal (JM frame), or packing (JP frame). ODP motors and stainless steel shafts are optional.

Interchangeable Part - Component parts of similar sizes are interchangeable with the Frame Mounted and Close Coupled Pumps. This means less spare parts inventory and fast delivery of required parts. CC pumps and parts manufactured by Summit Pump, Inc. are functionally and dimensionally interchangeable with the Peerless® C & F line manufactured by Peerless® Pump. Part for part interchangeability means you have a quality option when sourcing pumps or parts.

Mechanical Seal - Type 1 seal is standard; constructed of Carbon vs. Silicon Carbide faces, FKM elastomers and stainless steel metal parts. The maximum operating temperature rating is 150 o F with a standard seal in water. Higher temperatures are obtainable with optional seal materials.

316ss Wet End Option - 316ss wet ends are available for corrosive application. All wetted surfaces are constructed of 316ss including: Casing, Impeller, Adaptor, Sleeve, Washer, Impeller Screw and Key.

Motor - Premium efficiency NEMA JM Motor

Casing Designed For Easy Maintenance - Back pull out design allows maintenance of bearing frame without disturbing the suction and discharge piping. Multiple casing discharge positions are possible.

Wear Rings - Bronze wear rings are easily replaced and prevent casing wear. Rings are not required on 316ss wet ends.

Impeller - The enclosed impeller ensures the highest efficiency, and is hydraulically balanced which reduces axial thrust, and increases bearing life. The impeller is keyed and locked to the shaft.

In-stock Inventory ready for shipment.

Download Summit CC Pump Brochure

FM - Frame Mounted Pump

SUMMIT FM pumps are horizontal, end suction, centrifugal pumps certified to DOE requirements. They are an economical and dependable solution for general service such as clean water, solvents, light oils, non-corrosive chemicals, coolants and brines. Frame mounted pumps are constructed with a rigid bearing frame, flexibly coupled and mounted on a fabricated steel base with optional drip pan. The casing, adapters, and bearing frames share mating registers for maximum interchangeability. Coupling guards meet ASME B 15.1 specifications.

- Capacities to 2300 GPM

- Heads to 440 feet

- Fanges are 125lb ANSI B16.1 rating

- NPT connections are standard on 6” and most 8” sizes.

- A renewable bronze shaft sleeve is standard on cast iron pumps and a 316ss shaft sleeve is standard on alloy pumps.

Interchangeable Parts - Component parts of similar sizes are interchangeable with the Frame Mounted and Close Coupled Pumps. This means less spare parts inventory and fast delivery of required parts. FM pumps and parts manufactured by Summit Pump, Inc. are functionally and dimensionally interchangeable with the Peerless® C & F line manufactured by Peerless® Pump. Part for part interchangeability means you have a quality option when sourcing pumps or parts.

Mechanical Seals - Type 1 seal is standard; constructed of Carbon vs. Silicon Carbide faces, FKM elastomers and stainless steel metal parts. The maximum operating temperature rating is 150 o F with a standard seal in water. Optional seal materials are available for higher temperatures.

316ss Wet End Option - 316ss wet ends are available for corrosive application. All wetted surfaces are constructed of 316ss including: Casing, Impeller, Adaptor, Sleeve, Washer, Impeller Screw and Key.

Impeller - The enclosed impeller ensures the highest efficiency, and is hydraulically balanced which reduces axial thrust, and increases bearing life. The impeller is keyed and locked to the shaft.

Wear Rings - Bronze wear rings are easily replaced and prevent casing wear. Rings are not required on 316ss wet ends.

Bearings - Frame mounted pumps have regreaseable SKF single row deep groove ball bearings with a minimum B-10 life of 20,000 hours

Casing Designed For Easy Maintenance - Back pull out design allows maintenance of bearing frame without disturbing the suction and discharge piping. Multiple casing discharge positions are possible.

Extra Heavy Duty Shaft - Frame mounted pumps use a rigid 4140 steel shaft designed to maximize seal and bearing life with a maximum deflection of 0.002”.

In-stock Inventory ready for shipment.

Download Summit FM Pump Brochure