Product Description

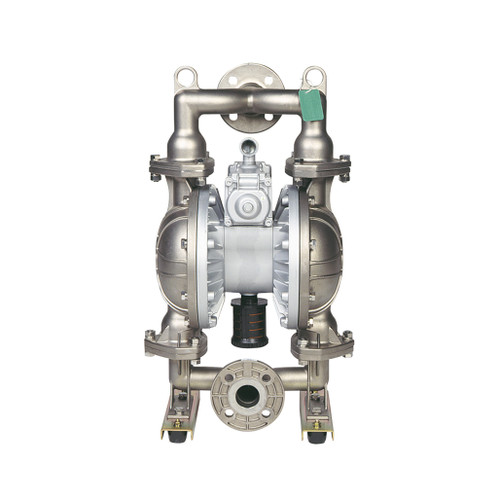

Yamada NDP-40BSC Air Operated Double Diaphragm Pump with 1-1/2" ANSI Flange Ports, Stainless Steel Construction and Neoprene Diaphragms makes this pump perfect for a variety of processing applications - Model 852419

NDP-40BSC Pump Materials of Construction:

- Body Material: Stainless Steel

- Elastomer Material: Neoprene

- Air Motor: Aluminum

| Manufacturer Part Number | NDP-40BSC |

| SKU | 852419 |

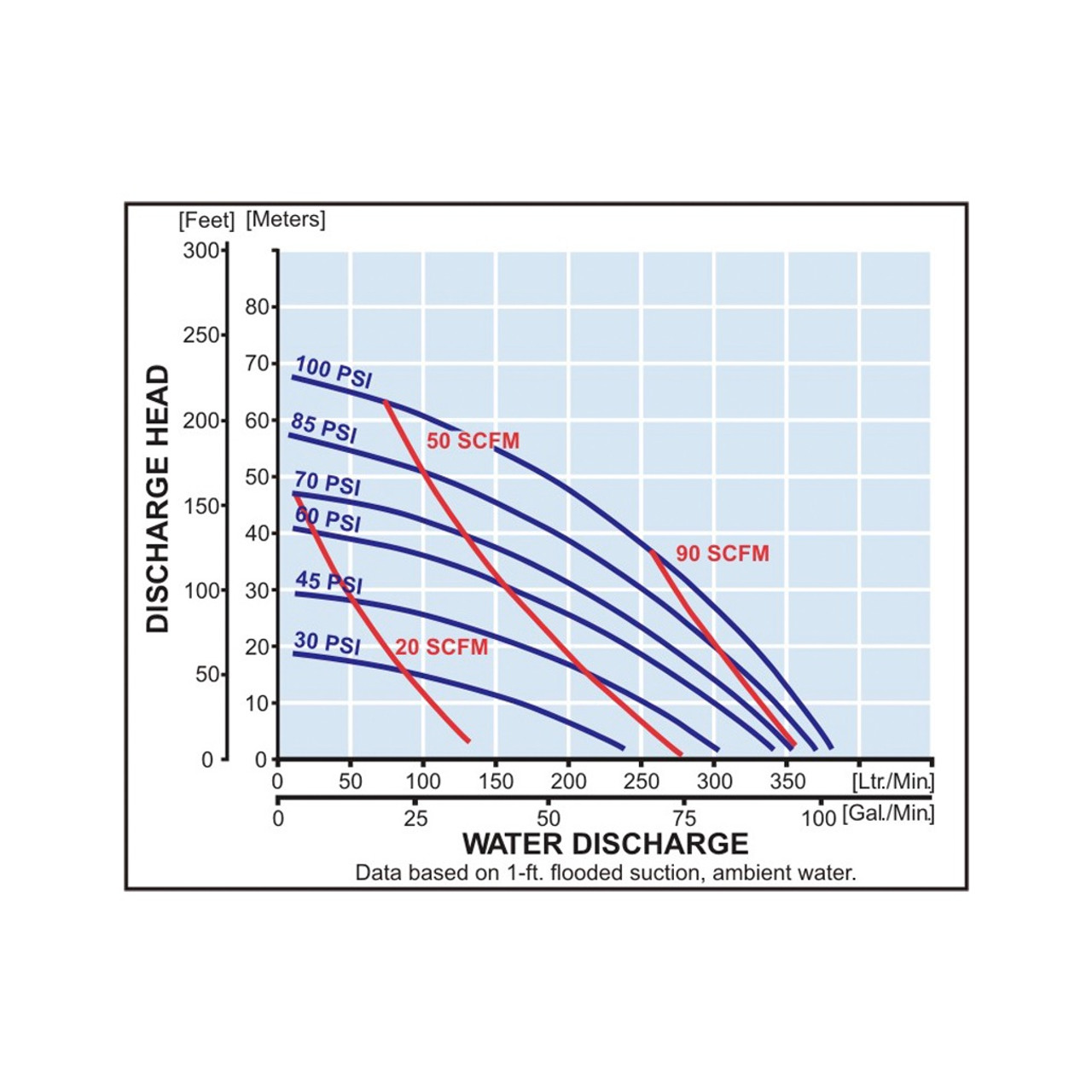

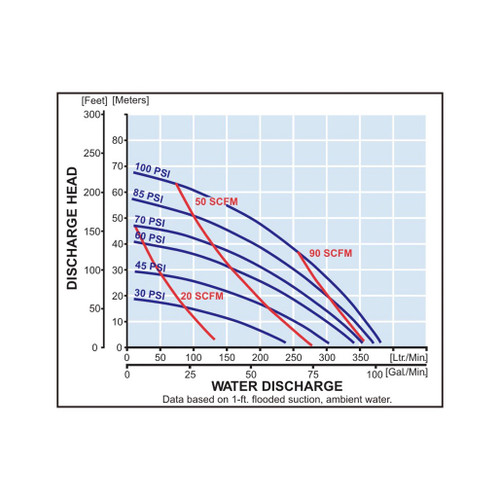

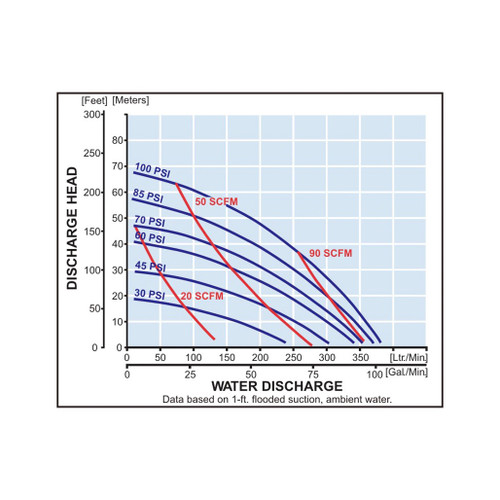

| Max Flow | 107 GPM |

| Max Head | 100 PSI |

| Discharge Volume per Cycle | 0.73 gallons |

| Intake & Discharge Connections | |

| Ports | 1-1/2" ANSI Flange B16.5 #150 |

| Air Inlet | 1/2" Female NPT (includes ball valve) |

| Air Exhaust | 1" Female NPT (includes silencer) |

Bill of Materials: Download

Data Sheets: Download

Suggested applications

Fluid Transfer, as in chemical, paint, adhesive and wastewater applications.

Viscous, abrasive, or flammable liquids like paints, polymers, acids, solvents, slurries and powder/liquid mixes.

The ability to handle challenging fluids and "deadhead" (or stall) without damage makes these pumps ideal for dosing, mixing, filter press feed, and general fluid transfer.

Other Details

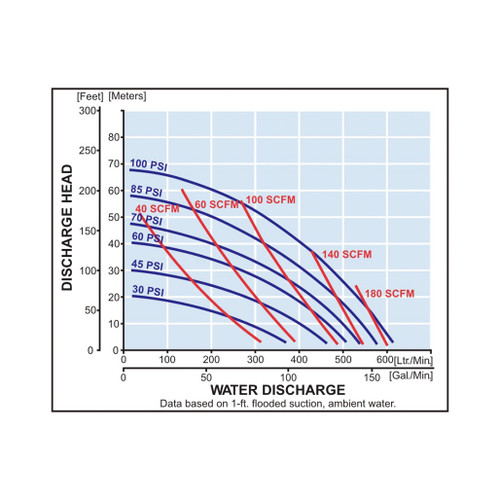

Yamada's NDP-40 series 1.5" AODD pumps provide a Max Flow Rate of 107 GPM and are available in Aluminum, Stainless steel (316), Kynar (PVDF), Cast Iron, and Polypropylene.

Download Full Yamada Pump Catalog

Engineered for High Performance and Long Life.

Rugged, Bolted Construction

All Yamada pumps feature bolted construction, which eliminates leaks and simplifies post-maintenance reassembly. Bolted construction is superior to clamp band retainers, which frequently require frustrating, unnecessary leakage rebuilds from misalignment during reassembly.

Outside-Accessible Air Valve

Inspection or maintenance of every Yamada air valve may be performed without removing the pump from service. Outside accessible, making it easy to fix and inspect.

Unified Air Valve Concept

Common-size air valve assemblies reduce parts confusion and inventory.

Pilot Valve

Unique to the Yamada design is an individual modular pilot valve that actuates the air valve. It is depressed slightly by the inner center disk creating a pressure drop at one end of the air valve, allowing shifting to occur. It is maintenance free with no cumbersome snap rings or lubricated dynamic o-rings to replace or repair.

What separates Yamada from the rest of the pack is the air valve technology. Yamada air valve technology is the heart of the air-powered double diaphragm pump and determines reliability. Yamada NDP series pumps use a completely non-lubricated main air valve and independent pilot mechanisms to control the air logic, called a C-spool ensures stall-free operation throughout product life.

Yamada holds three patents on its field proven valve and enjoys a superior reputation throughout the industry.

How Yamada AODD Pump Air Valve C-Spool Works

- As compressed air enters the pump, it is directed via the main air valve to one side or the other, depending upon the starting position of the c-spool.

- As the air enters the chamber, it forces the diaphragm outward.

- This outward momentum forces liquid out of the discharge ball valve and loads the opposite inlet ball valve.

- As the diaphragm travels outward, the connected diaphragm on the opposite side is pulling the diaphragm inward.

- When it travels a full stroke, it will contact the pilot valve, depressing it and breaking the seal to open an exhaust port.

- The open port allows the compressed air to the exhaust from the back side of the air valve. The pressure drop produces a shift of the main air valve.

- This motion simply repeats on the other side.

Yamada's One-Year Limited Warranty

Yamada air operated diaphragm pump series are warranted by YAMADA to the original user against defects in workmanship or materials under normal use for one year from date of purchase. Download Yamada Warranty